A saddle key is simply mounted on the shaft and inserted into the keyway which is provided only in the hub. Keyway in the shaft is not required.

Saddle keys are used for very light loads.

To fit the saddle key, the groove is made in the pulley only. The grip of the saddle key is due to friction on the shaft.

These types of keys are rarely used in industry because they are not able to provide high torque and load.

Working Principle of Saddle Key

The working principle of a saddle key is based on the friction between two surfaces that is responsible for the transmission of power.

Types of Saddle Key

There are two types of saddle keys:

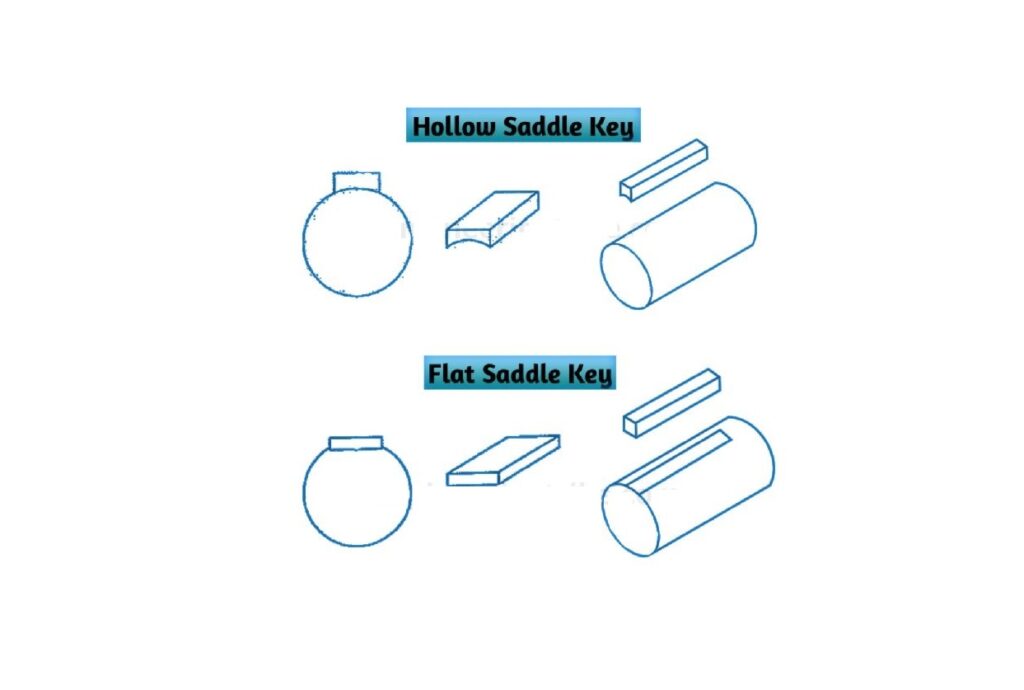

- Hollow Saddle Key

- Flat Saddle Key

Hollow Saddle Key

A hollow saddle key is mounted on the shaft only.

In a hollow saddle key, the lower part of the key is made hollow, this hollow part holds the shaft firmly due to friction.

Hollow saddle keys are used for very light loads.

It is used as a temporary fastener in eccentrics and cams.

The bottom of the key is shaped to fit the curved surface of the shaft.

Hollow saddle keys can be used for relatively larger loads than flat saddle keys because hollow saddle key has large friction between the key & shaft.

Flat Saddle Key

A flat saddle key is mounted on the shaft only as a keyway is not required in the shaft. The entire key fits into the hub.

The motion is transmitted due to friction between the key and the shaft. It is used to transmit light loads.

In a flat saddle key, the key remains flat, and the part of the shaft on which the key fits is made flat.

Advantages of Saddle Key

In the saddle key the manufacturing and implementation cost is low and also the implementation process is easier than in other types of key.

Disadvantages of Saddle Key

- Saddle keys are primarily used for low-duty work or transmissions.

- It can not handle much slip-resistant.